How does a manufacturer automate logistics operation in their warehouse?

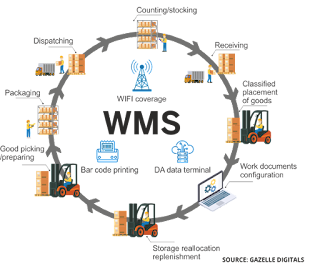

In the manufacturing industry, warehouses are at its core. Logistics operations in a warehouse include the flow of both physical goods and information. This includes the flow (shipping and receiving) of physical inventory, as well as that of more abstract goods, including information and time. Automation and control of the warehousing operations can be done in three steps: 1. Invest in the latest technology hardware to accurately manage inventory. For example, label every material you procure by using the latest technology like – RFID tag, barcode, and QR code 2. Use a powerful software to perform complex processes, calculate algorithms and select a suitable stock control methodology for you. 3. Integrate the hardware and the software by means of an automated solution. Warehouse Management System ( WMS ) comes handy in an ERP solution . Advanced warehouse management system ( WMS System ) gives you real-time insight into your warehouse, and equips you – and all your employees – with t...